You can piece together your entire AR-15 from barrel to buttstock, but there’s one single part that you’ll need to make it fully complete and legally yours… Your AR-15 Lower Receiver. Sure you have to pass a background check to even get one, but there’s much more to picking the right Lower to complete your build. We’re here to help!

Table of contents

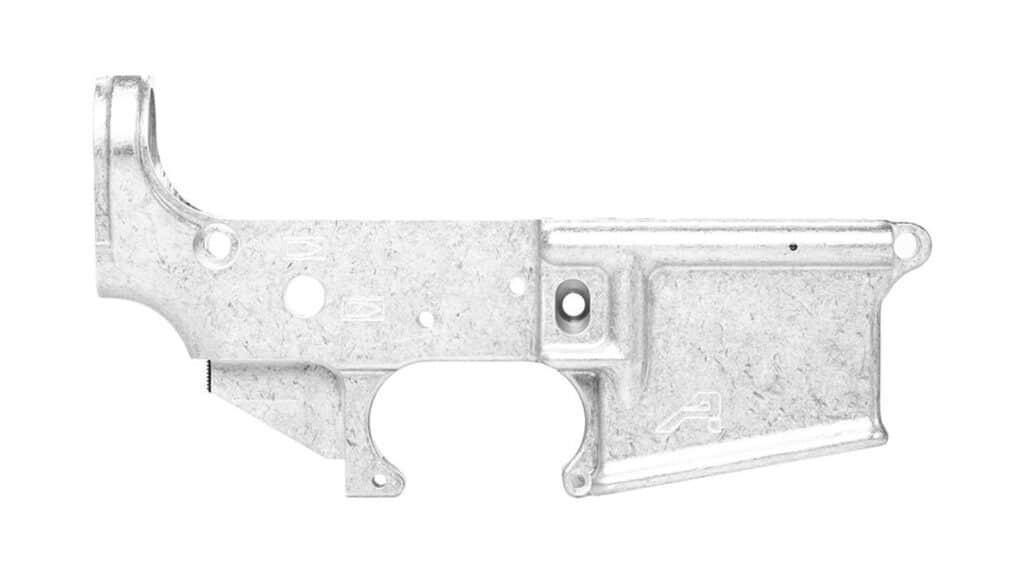

The AR15 Lower Receiver

Why is the lower the most important? Simple – it’s the part that holds all the other bits and pieces that make the gun go “BANG”. Your trigger, safety, magazine catch, and bolt catch, plus the buffer system. Most of the essential controls are housed in the lower – meaning you can’t do anything without them.

The lower receiver is so important that the ATF considers it the “firearm”, the part that must be serialized, and what you’ll receive a background check for. Without that serial number, it’s one of the dreaded “ghost guns” (more on that a little later). All the other pieces are just accessories – necessary maybe, but accessories are just the same.

You will usually see AR platform components including receivers referred to as mil-spec. In a nutshell, mil-spec simply means that they conform to military manufacturing specifications.

What does that mean? It means that parts interchangeability is off the charts! That makes America’s favorite rifle practically akin to Legos.

So how do you choose a lower receiver? Should be easy, right?

Maybe not. When you start diving into specifications, you’ll see things like:

- Billet vs Forged Aluminum

- 6061-T6 vs 7075-T6 Aluminum

- Raw, Anodized, and Cerakote

Even injection-molded polymer, which we’ll address last. After that, there’s the level of completion. Do you know the difference between:

- 80% Lower Receivers

- Stripped Lower Receivers

- Complete Lower Receivers

Caliber is a concern too. How do you know you’ll get the right setup for the cartridge you have in mind?

Is your head spinning yet? Let’s try to break it down so you can make an informed decision based on your wants and needs.

Almost everything here will start an argument over some little detail or value judgment. The only important takeaway is that, by the end, you’ll have the knowledge to decide what’s important to you.

Before we get started, answer a short question. Which is better: a tank, or a Ferrari? The answer seems simple if what matters to you is looking good and going fast. What if I want to use it to thrash through a mud bog and push down small trees? That might change your decision.

AR15 Lower Receiver Material

Let’s start with the material. A mil-spec receiver will be made of aluminum. Aluminum for ARs is typically 6061-T6 or 7075-T6.

The 7075-T6 is much stronger – coming close to the strength of some steels. Mil-spec requires only 7075-T6. So why is 6061-T6 used? Simple – because it’s cheaper to make. It has close to half the strength of 7075-T6, and it’s much easier to machine. It costs less in time and tooling, so of course manufacturers love it.

But wait – isn’t that dangerous? Who would want a weaker firearm? Remember the tank analogy? That mil-spec material will give you a firearm that’s suited for actual combat with its associated abuse and neglect. Unless you really need that, the choice of materials for a safe firearm is open.

The ultimate strength of a 6061-T6 receiver is absolutely safe and suitable for hunting, self-defense, and range use. It’s not mil-spec, but most of whatever gun you build won’t be “mil-spec” anyway.

What about polymer lowers?

There is often a debate surrounding the superiority of polymer lowers compared to their metal counterparts, which largely depends on the manufacturer. Some firearm enthusiasts argue that opting for a polymer receiver may give the impression of handling an airsoft toy rather than a serious rifle. However, polymer lowers can be a viable option if a lightweight platform is your primary concern.

One advantage of polymer lower receivers is their lower cost compared to aluminum receivers. Additionally, they can be easily machined due to the softer nature of the material, as opposed to the challenges of machining metal.

In recent years, advancements have been made in the manufacturing process of polymer lowers, with the addition of fibers to enhance stress reinforcement. This has led to videos surfacing of individuals subjecting their rifles with polymer receivers to rigorous stress tests, even running over them with a truck, in order to gauge their durability.

AR15 Lower Manufacturing System

Now let’s complicate the decision-making process. Just a little bit. Don’t worry we still have your back.

Do you want billet or forged construction? Mil-spec calls for forged receivers in which a block of aluminum is heated up enough to slightly soften it and is then hammered or pressed into a two-part mold that’s roughly the shape of the finished receiver. Then, it’s machined to the final dimensions.

On the other hand, Billet receivers start with a rectangular block of aluminum, and excess material is machined away until all that is left is the finished lower receiver. Many billet receivers are made from 7075-T6, but some lower-cost options are made of 6061-T6. This is mostly a cost-saving measure since the latter needs less time on the machine to be properly milled.

Toss the lab coat on for a second and come hither! Let’s talk about metallic grain structure. Metal at a microscopic level has crystalline structures known as “grains”. The size and chemical (metallic) composition of these structures helps determine how hard a material is.

In the forging process, the metallic grain structure ( in the original blank is stretched and aligned with the receiver shape, resulting in much higher tensile strength. In the billet process, the grain remains as it was in the original billet, so grains are interrupted in the process of removing material. The tensile strength of billet construction is typically lower than forged.

So forging is better – right? If you need that tank, absolutely. That’s why mil-spec receivers are forged. But in most billet designs, safety is taken into account, typically making it a non-issue. That additional tensile strength is only essential in the most extreme environments and use cases.

In addition to strength, a major argument for forging is cost. Because of the typically reduced time spent machining, good “mil-spec” lowers are less expensive than billet lowers.

On the other hand, billet receivers are much more versatile. The manufacturer can incorporate additional material in stress points while removing an enormous amount of material in unstressed areas to reduce weight without losing strength. Plus, many billet lowers add unique features like flared magazine wells, or ambidextrous controls.

Another option for billet receivers is significantly increasing receiver wall thickness to improve rigidity, and thus accuracy. In this case, the upper receiver must be purchased with the lower to assure a match between the upper and lower.

What about the cost? Generally, even with the 6061-T6 material, prices tend to be higher due to the significant amount of machining and associated scrap material. The addition of extra machining for lightness and strength can bring the costs higher than most folks are willing to bear when it comes to buying a lower receiver.

Level of Completion

The next decision you must make before buying your first component is just how much work you want to do yourself.

Stripped AR15 Lower Receivers

If the thought of spending your time on machining and legal research isn’t your thing, you can opt for what most builders do: a stripped lower. This is a completely machined lower but without any of the pieces that make it work (trigger, safety, pins, springs, etc.).

The stripped lower is considered a firearm, has a manufacturer’s serial number, and can only be purchased through a dealer licensed as an FFL (Federal Firearms Licensee). Purchase of a stripped lower requires a background check just as if you were purchasing a complete firearm.

Assembling a stripped lower can still be tricky, with tiny springs and pieces trying to fly away and vanish somewhere in your work area, and you’ll likely need tools like punches, an armorers’ wrench, and specialized vise blocks. For a full breakdown of the parts in an AR lower, check out this FREE Army Service Manual.

Complete AR15 Lowers

If you’re really in a hurry to build your AR-15, or if you really hate handling numerous small parts (about 37 of them), a complete lower may be for you. Complete lowers take all the fussing complete out of the equation. You’re ready to add an upper receiver assembly and a magazine!

The 80% Lower Receiver

What are 80 percent lower receivers? They are machined piece of metal that is 80% of the way to being a lower receiver. There is still machining, drilling, etc required to get it the rest of the way. With an appropriate jig and the fairly inexpensive end mill bit and drills, an 80% blank could be turned into a fully functional lower receiver.

Without getting too into the weeds on legislation It should be mentioned that this is an ever-moving target. Lately, things like 80% receivers, 3D printed guns, and “ghost guns” as a whole category have been on a carousel when it comes to laws and regulations; state-wise and federally. We will update this when things become more stable regarding 80% Lowers.

Full 08/26/2022 Rule AVAILABLE here at ATF.GOV

For more current information on this subject, we encourage you to view any updates on the ATF website.

AR15 Lower Receiver Finishes

Now that you’ve settled on what kind of AR-15 lower receiver you want, you have to consider finishes. Most lower receivers ship with a black hard anodized finish. If you want to finish it yourself in some color that means something to you, you could potentially special order your lower unfinished.

There is also a costly process called anodizing which is a process similar to electrolysis but instead of plating it involves the use of dye.

The final finish possibility is “Cerakote”, which is a proprietary ceramic finish. It can be applied in every color of the rainbow, but receivers are commonly colored in “military” colors like Black, FDE (faded dark earth), Coyote Tan, Olive Drab, etc. Typically a Cerakote finish adds between $20 and $40 to the receiver price.

We typically offer many of our products in around 10 colors.

- Black

- Red

- Blue

- Pink

- Grey

- OD Green

- Flat Dark Earth

- Burnt Bronze

- Tungsten

- Titanium

AR15 Lower Receiver Caliber

If you’re going to fire one of the dozens of rifle calibers available to the AR-15 platform (5.56 NATO, 300 Blackout, 6.5 Grendel, etc.) you’ll need a standard mil-spec AR-15 lower receiver just as we’ve seen so far. If you’re going to fire pistol rounds (9mm, 45 ACP, etc.), you’ll need a special lower receiver designed for that purpose.

Available Selections

When it comes to lower receivers, there’s a huge variety to choose from! Forget about those cheap imports and tiny unreliable companies. We prefer suppliers who handle everything in-house rather than relying on a sub-supplier. There is one major exception to this. Because of the complexity and size of the required facility, virtually all suppliers rely on one of a few suppliers for the forged blanks prior to final machining.

From our experience, there are a few suppliers whose lowers range from basic economical models to ultra-high-end specialty models, yet still meet our high standards for quality and reliability.

Aero Precision

Up next, we have Aero Precision, offering top-notch products that not only look great but also come with handy features to ease the worries of homebuilders. These lowers are cleverly designed with threads to keep springs and pins in place during assembly, preventing any wild part escapades.

With cool extras like receiver tensioning screws and beveled magazine wells, Aero Precision rifles not only outperform their rivals but also feel fantastic in your hands. Prices for Aero Precision AR-15 lower receivers start at just $100, while complete lowers begin at around $225. Get your hands on one and experience the difference!

Anderson AM15

Check out Anderson Manufacturing! They’ve mastered the art of providing top-notch quality at a reasonable price. They make everything in-house, and their attention to detail is seriously impressive.

Take their AR-15 Lower Parts Kits, for example. While others simply toss the bits and pieces into a plastic bag, Anderson goes the extra mile by neatly arranging each part in a snug, plastic tray. No more struggling to keep track of those tiny pieces while you’re installing them! Plus, their stripped lower receivers are usually less than $100, and their awesome complete lower receivers start at just over $150.

KE Arms

KE Arms offers very high-quality billet lowers and high-end complete lower assemblies. While their billet lowers are feature-rich, they sell monolithic injection molded polymer lower receivers, with an integral buttstock and pistol grip. The KP-15 and its pistol-caliber sibling, the KP-9, are tough as nails and surprisingly lightweight.

KE Arms offers excellent quality billet lowers starting around $300, with top-end complete assemblies running around $700. The KE Arms polymer receivers start at around $100 stripped. The complete lowers, depending on features, run anywhere from $250 to $550.

Angstadt Arms

Angstadt Arms excel in producing precisely machined AR-15 receivers as perfectly matched sets. What sets them apart is their specialization in pistol caliber AR-15s, specifically designed to utilize Glock magazines in 9mm, .40 S&W, .45 ACP, and 10mm. With a focus on quality, Angstadt Arms manufactures its products in-house, employing skilled gunsmiths who take pride in their work. Their lowers start at a reasonable $280, while complete lowers begin at $600.

Decision Time

You’ve got all the options, and I bet you’re still unsure about what to buy. But hey, that’s the fun part of life! First, prioritize what you must have, and then go for what you want.

Consider your needs: if it’s for home defense, reliability is a must—no questions there. If you’re looking for a range gun, accuracy is key. If you plan to go hunting and hiking, think about the weight. And if you’re into heavy-duty, professional stuff like security or combat, durability is non-negotiable.

Once you’ve figured out your needs, it’s time to indulge in what you want and what fits your budget. The choice is all yours, and we hope we’ve given you enough to make a wise decision. Now, go out there and have a blast building that gun!

FAQs

For an ordinary stripped lower receiver you are looking at an average starting price of $50 to $100. Complete lowers will often toss another hundred or two onto that.

Yes. Lower receivers are the regulated portion of a gun. They are the firearm. You will need to have the lower receiver transferred from an FFL to you.

No. 80% receivers are not banned however rules regarding and including them have recently changed and are subject to potential further change. As of 6/2023, these types of lowers are regulated in the same way that normal firearms are. They require a background check and transfer from an FFL.

No. In fact, most AR lower receivers will be marked “multi”. The only time cartridge concerns come into play is when you are dealing with AR15 cartridges vs AR10 cartridges.

Yes. AR15 lower receivers can be used with a number of cartridges (.204 Ruger, .223/5.56, .22 Nosler, .224 Valkyrie, .25-45 Sharps, 6.5 Grendel, 6.8 SPC .300 Blackout, .300 Ham’r, .30 Remington AR, .350 Legend, .450 Bushmaster, 50 Beowolf, etc) and the list ever continues. Just make sure that your barrel is chambered for the intended cartridge.

One Last Tip

If there’s anyone that knows the AR-15 platform, it’s the US military. As a special offer for our readers, you can get the Official US Army Manual for AR-15/M4/M16 right now – for free. Click here to snag a copy.

BUT:

Which lowers FIT .410 Bore Shotgun Mags???

This article otta be a “must read-then decide” that the more experienced shooter/builders can show to a newbie to explain the metalurgical difference of billet/forged 6061vs 7045 and cost variances without it going over their heads. I woud though have liked a bit more on the polymer end pointing out how you can also find a Bob’s Backyard Discount Gun Garage reliability vs the quality standards of a brownells or palmetto arms etc

Are 80% lowers still available?

Interesting read on AR9 lowers

🙂

Thank you, for the in depth information.

You omitted a discussion of options for the FCG pocket. While few, if any “high shelf” stripped lowest are made any more, someone interested in expanding their knowledge base could benefit from learning that difference as well as the fact that there are a few manufacturers, like Centurion Arms & Matrix Arms, that still produce lowers with “true” mil-spec FCG pockets (minus the infamous “3rd hole”) for those that after the most authentic reproduction (minus the prison term).

Anderson also has a M-16 FGC pocket model. Again without that 3rd hole.