AT3 Tactical Terms of Use Agreement

Last Updated: January 5, 2022

This Terms of Use Agreement (“Agreement”) governs your use of and purchase of products from the AT3 Tactical website and your use of that website’s associated content (collectively, “Website”). The Website is owned and operated by AT3 Tactical, LLC, a Minnesota limited liability company (“AT3”). This Agreement and the terms contained herein is subject to change by AT3 at any time, in its sole and absolute discretion, and without notice. Therefore, you are instructed to review the terms of this Agreement prior to using the Website. If you do not agree to the terms and conditions contained within this Agreement, you must discontinue your use of the Website immediately. Your continued use of the Website after a replacement, modification, or amendment of the terms of this Agreement will constitute your manifestation of assent to, and agreement with, any replacement, modification, or amendment herein.

AT3 hereby incorporates its Privacy Policy as if fully restated herein. You are instructed to review AT3’s Privacy Policy to understand the personal and personally identifiable information that AT3 may collect from you when you use the Website and how AT3 may use that personal or personally identifiable information.

NOTICE OF ARBITRATION. THIS TERMS OF USE AGREEMENT CONTAINS AN ARBITRATION PROVISION AND CLASS ACTION WAIVER. EXCEPT AS OTHERWISE STATED UNDER THE TERMS OF THIS AGREEMENT, AND IF YOU DO NOT OPT-OUT OF ARBITRATION AS SET FORTH BELOW, YOU AGREE THAT ANY AND ALL DISPUTES BETWEEN YOU AND AT3 WILL BE RESOLVED BY BINDING, INDIVIDUAL ARBITRATION, AND YOU WAIVE YOUR RIGHT TO BRING OR RESOLVE ANY DISPUTE AS, OR PARTICIPATE IN, A CLASS, CONSOLIDATED, REPRESENTATIVE, COLLECTIVE, OR PRIVATE ATTORNEY GENERAL ACTION OR ARBITRATION.

a. Eligibility to Use the Website

The Website is open to use by US residents who are age eighteen or above. By using the Website, you warrant that you are age eighteen (18) or above, are of sound mind, and have the capacity to agree to and uphold the terms and conditions contained within this Agreement. If you use the Website on behalf of a business entity or other third party, you warrant that you express actual authority to act as an agent of that business entity and third party and, as a component of that agency, have the right and ability to agree to the terms of this Agreement on behalf of that third party or business entity.

b. Acceptable Use of the Website

When you use the Website, you agree to use it only for its customary and intended purposes and as permitted by the terms of this Agreement and any applicable law, regulation, statute, or ordinance. Additionally, you agree that you are responsible for any breach of your obligations under the terms of this Agreement and for any losses suffered by AT3 for such a breach, including, but not limited to, monetary damages, costs, and attorneys’ fees. You are expressly prohibited from using the Website to violate any law, statute, ordinance, regulation, or treaty, whether local, state, provincial, national or international, or to violate the rights of a third party, including, but not limited to, intellectual property rights, privacy rights, rights of publicity, or other personal or proprietary rights. Additionally, you are expressly prohibited from:

· Attempting to access the Website other than through a standard web browser unless you have been permitted to do so by AT3 through a separate, written agreement;

· Accessing or attempting to access the Website through automated means;

· Circumventing the technological protection measures of the Website;

· Disrupting or otherwise interfering with the Website or its associated servers or networks;

· Scraping, reproducing, republishing, selling, reselling, duplicating, or trading the Website;

· Diverting or attempting to divert customers of the Website to another website or service;

· Sending unsolicited or unauthorized communications to users of the Website or third parties;

· Reverse engineering, decompiling, translating, or disassembling the Website or its content; and

· Encouraging or assisting any other party to do anything in violation of the terms of this Agreement.

AT3 reserves the right to modify, amend, or terminate the Website or its associated content at any time and without prior notice. AT3 also reserves the right to refuse service or access to the Website to any person or business entity at any time and without notice.

c. Limited License to Use the Website

You acknowledge and agree that the Website is the property of or is licensed by AT3 and is protected under United States and international law, including, but not limited to, intellectual property laws and other personal and proprietary rights. You acknowledge and agree that your use of the Website is limited by the license granted under the terms of this Agreement, and you expressly agree that you will not use the Website in any manner not expressly authorized under the terms of this Agreement. AT3 reserves all of rights not expressly granted through this Agreement.

AT3 provides you with a limited, non-exclusive, non-sublicensable, non-assignable, revocable, and royalty free license to use the Website for its customary and intended purposes. You are expressly prohibited from reproducing, preparing derivative works of, distributing copies of, publicly performing, and publicly displaying the Website.

When using the Website, you grant AT3 an irrevocable, perpetual, sublicensable, transferable, non-exclusive, and royalty-free worldwide right and license to use, copy, modify, adapt, publish, transmit, perform, create derivative works from, and display publicly throughout the world and in any medium or form now existing or later created any content that you submit to the Website, including, but not limited to, testimonials submitted to AT3 arising out of the purchase of products from the Website. You expressly agree that AT3 may use this content for any purpose and that the use or republication of this content will be at AT3’s discretion and without compensation or attribution of any kind.

d. Orders and Payment

Each order submitted to AT3 through the Website is an offer to AT3 to buy the product(s) listed in the order. When you place an order to purchase a product through the Website, AT3 will send you an email confirming receipt of your order. Your receipt of this email confirms that you have placed an order, and you understand and agree that this email does not constitute AT3’s acceptance of your order. No order will have been deemed to have been accepted by AT3 until the product(s) contained within the order is shipped by AT3 to you.

You must be at least eighteen (18) years old to purchase rifles or shotguns through the Website and twenty-one (21) years old to purchase handguns or receivers through the Website. You understand and agree that any firearms purchased by you through the Website must be shipped to a Federal Firearms Licensed dealer within your location. You also understand and agree that you may receive your firearm from the licensed dealer that receives it only if you pass a National Instant Criminal Background Check conducted by the dealer. The Federal Firearms Licensed dealer may also charge you additional transfer or background check fees for their services. You understand and agree that AT3 is not responsible, and will not be held responsible, for fees charged by Federal Firearms Licensed dealers and you are solely responsible for paying all such fees.

All firearms sales are final, non-refundable, and cannot be returned to AT3 without prior authorization. If a firearm must be returned due to a failed background check or similar reason, we will charge a 15% restocking fee that will be deducted from the refund. AT3 reserves the right to modify its policies related to firearm sales through the Website at any time, without notice, and in its sole and absolute discretion.

Payment for all orders placed through the website must be made at the time of ordering. You agree that you will pay all applicable taxes or charges imposed by any governmental entity anywhere in connection with your use of the Website or purchase of goods through the Website. All costs and fees are quoted and payable in United States Dollars and you acknowledge and agree that AT3 is not responsible for any transaction fees or other fees charged to you by your financial institution or by AT3’s payment processor. You agree that you will not initiate any chargebacks to AT3 unless otherwise authorized by AT3 in writing. You understand and agree that you will be responsible and required to pay for any costs associated with any chargebacks that you have initiated against AT3.

Note to Alabama customers: AT3 Tactical will collect the Simplified Sellers Use Tax (SSUT) of 8% on taxable customer transactions delivered into Alabama. The tax will be remitted on the customer’s behalf to the Alabama Department of Revenue. The Seller’s program account number is SSU-R010896575

e. Returns and Refunds

Our returns and refunds policy is available here at the below URL.

AT3 Returns Policy

f. Product Pricing and Availability

While AT3 strives to provide accurate prices for its products and to have regular access to sufficient inventory, it is possible that AT3 may, from time to time, mistakenly list a product’s price or stock. If this occurs, AT3 will contact you within a reasonable time frame to advise you of the mistake. You understand and agree that the price or availability of a product displayed through the Website does not guarantee that the product will be in stock, sold at the listed price, or that your order can be immediately fulfilled by AT3.

g. Shipping

All products purchased through the Website are shipped Free Carrier (F.C.A.) and the risk of loss and title passes to you upon delivery to the carrier. AT3 will pay for the shipping costs of returning a non-firearm product to AT3 if the product in question is defective. If you return a product that was not defective, AT3 reserves the right to deduct the cost of return shipping from the amount refunded to you.

You understand and agree that products sold through the Website are shipped and sold in accordance with federal, state, and local laws and regulations. Many items sold through the Website may be restricted or prohibited in your area and you are advised to research your local and state regulations before ordering.

Further policy details can be found at the below URL.

AT3 Shipping Policy

AT3 reserves the right to modify its shipping policies at any time, without prior notice, and within its sole and absolute discretion.

h. Trademarks

You acknowledge and agree that any and all trademarks, trade names, design marks, or logos displayed on the Website by AT3, including but not limited to AT3, are common law or registered trademarks owned by or licensed to AT3. You are expressly prohibited from using the trademarks of AT3 to cause confusion in, to cause mistake in, or to deceive consumers, or from falsely designating the origin of, the source of, or the sponsorship of your goods or services. You are further prohibited from using the trademarks of AT3 in domain names, in keyword advertisements, to trigger keyword advertisements, or in meta tags. All other trademarks, trade names, design marks, or logos are the property of their respective owners.

i. Term and Termination

The term of this Agreement will begin upon your first accessing of the Website and will continue until the earlier of the following: (i) AT3 terminates your access to the Website; or (ii) you cease using the Website and terminate your Account. AT3 reserves the right to terminate the Website or your access to the Website in its sole and absolute discretion and without prior notice.

j. Disclaimer of Warranties and Limitation of Liability

YOU ACKNOWLEDGE AND AGREE THAT THE WEBSITE IS PROVIDED ON AN “AS-IS” BASIS AND WITHOUT WARRANTY OF ANY KIND, INCLUDING, BUT NOT LIMITED TO, WARRANTIES OF TITLE, MERCHANTABILITY, ACCURACY, FITNESS FOR A PARTICULAR PURPOSE, SECURITY, AND NON-INFRINGEMENT. WHEREVER PERMITTED BY LAW, YOU ACKNOWLEDGE THAT AT3 WILL NOT BE HELD RESPONSIBLE OR LIABLE FOR ANY CLAIMS, DAMAGES, JUDGMENTS, CHARGES, OR FEES ARISING OUT OF OR RELATED TO YOUR USE OF OR ACCESS TO THE WEBSITE, INCLUDING, BUT NOT LIMITED TO, COMPENSATORY DAMAGES, CONSEQUENTIAL DAMAGES, SPECIAL DAMAGES, INCIDENTAL DAMAGES, PUNITIVE DAMAGES, EXEMPLARY DAMAGES, COSTS, AND ATTORNEYS’ FEES, DAMAGES ARISING OUT OF ERRORS OR OMISSIONS, AND DAMAGES ARISING OUT OF THE UNAVAILABILITY OF THE WEBSITE OR DOWNTIME. YOU ACKNOWLEDGE THAT YOUR USE OF THE WEBSITE IS AT YOUR SOLE RISK AND THAT AT3’S LIABILITY IS LIMITED TO THE AMOUNT THAT YOU PAID TO USE THE WEBSITE OR $1000, WHICHEVER IS LESS.

AT3 EXPRESSLY DISCLAIMS ANY RESPONSIBILITY FOR ANY DAMAGE, INJURY, HARM, COST, EXPENSE, OR LIABILITY ARISING OUT OF OR RELATED TO YOUR USE OR MISUSE OF PRODUCTS PURCHASED THROUGH THE WEBSITE. EXCEPT FOR THE WARRANTIES SPECIFICALLY STATED IN THIS AGREEMENT, PRODUCTS PURCHASED THROUGH THE WEBSITE ARE PROVIDED WITHOUT EXPRESS, IMPLIED, OR STATUTORY WARRANTIES, INCLUDING, BUT NOT LIMITED TO, WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PUPOSE, TITLE, ACCURACY, NON-INFRINGEMENT, OR QUALITY. SOME JURISDICTIONS DO NOT ALLOW AN EXCLUSION OF IMPLIED WARRANTIES. IF YOU ARE LOCATED IN SUCH A JURISDICTION, YOU ARE ADVISED TO SEEK LEGAL ADVICE TO DETERMINE IF THIS EXCLUSION APPLIES TO YOU.

AT3 WILL NOT BE LIABLE TO YOU UNDER ANY LEGAL THEORY, WHETHER IN WARRANTY, CONTRACT, STRICT LIABILITY, TORT, PERSONAL INJURY, OR NEGLIGENCE, FOR ANY DAMAGES, CLAIMS, INJURIES, JUDGMENTS, COSTS, OR LIABILITIES OF ANY KIND ARISING OUT OF OR RELATED TO YOUR USE OR MISUSE OF PRODUCTS PURCHASED THROUGH THE WEBSITE, INCLUDING, BUT NOT LIMITED TO, PERSONAL INJURY, DAMAGE TO PROPERTY, DEATH, LOSS OF BUSINESS, LOSS OF INCOME, SPECIAL DAMAGES, INCIDENTAL DAMAGES, CONSEQUENTIAL DAMAGES, PUNATIVE DAMAGES, OR EXEMPLARY DAMAGES, WHETHER FORESEEABLE OR UNFORESEEABLE. YOU ACKNOWLEDGE THAT YOUR USE OF PRODUCTS PURCHASED THROUGH THE WEBSITE IS AT YOUR SOLE RISK AND THAT AT3’s LIABILITY IS LIMITED TO THE AMOUNT THAT YOU PAID FOR THE PRODUCTS OR $1000, WHICHEVER IS LESS.

k. Indemnification

You agree to indemnify, defend, and hold harmless AT3, its officers, shareholders, directors, employees, subsidiaries, affiliates, and representatives from any and all losses, including, but not limited to, costs and attorneys’ fees, arising out of or related to (i) your use of the Website, (ii) your purchase of products through the Website; (iii) your use or misuse of products obtained through the Website; (iv) your violation of any term or condition of this Agreement; (v) your violation of the rights of third parties, including, but not limited to, intellectual property rights or other personal or proprietary rights; and (vi) your violation of any law, statute, ordinance, regulation, or treaty, whether local, state, provincial, national or international. Your obligation to defend AT3 will not provide you with the ability to control AT3’s defense, and AT3 reserves the right to control its defense, including its choice of counsel and whether to litigate or settle a claim subject to indemnification.

l. Choice of Law and Stipulation to Jurisdiction

You and AT3 agree that any dispute arising out of or related to this Agreement or your use of the Website, including, but not limited to, your purchase or use of products from or through the Website, will be governed by the laws of the State of Minnesota, without regard to its conflict of laws rules. Specifically, the validity, interpretation, and performance of this Agreement will not be governed by the United Nations Convention on the International Sale of Goods. Except for claims for injunctive relief by either party, you and AT3 agree that any dispute or controversy arising out of, in relation to, or in connection with this Agreement or your use of the Website including, without limitation, any and all disputes, claims (whether in tort, contract, statutory, or otherwise) or disagreements concerning the existence, breach, interpretation, application or termination of this Agreement, will be resolved by final and binding arbitration pursuant to the Federal Arbitration Act in Hanover, Minnesota or, at the option of the party seeking relief, by telephone, online, or via written submissions alone, and be administered by the American Arbitration Association (“AAA”) under the then in force Commercial Arbitration Rules by one arbitrator appointed in accordance with such rules. Such arbitration will be independent and impartial. If the parties fail to agree on the arbitrator within twenty (20) calendar days after the initiation of the arbitration hereunder, AAA will appoint the arbitrator.

This arbitration will be conducted in the English language. The decision of the arbitrator will be final and binding on the parties and judgment on any award(s) rendered by the arbitrator may be entered in any court having jurisdiction thereof. Nothing in this section will prevent either party from seeking immediate injunctive relief from any court of competent jurisdiction, and any such request shall not be deemed incompatible with the agreement to arbitrate or a waiver of the right to arbitrate. The parties undertake to keep confidential all awards in their arbitration, together with all confidential information, all materials in the proceedings created for the purpose of the arbitration and all other documents produced by the other party in the proceedings and not otherwise in the public domain, save and to the extent that disclosure may be required of a party by legal duty, to protect or pursue a legal right or to enforce or challenge an award in legal proceedings before a court or other judicial authority. The arbitrator shall award all fees and expenses, including reasonable attorney’s fees, to the prevailing party. Any judgment rendered by the arbitrator may be entered in any court of competent jurisdiction.

ANY DISPUTE RESOLUTION PROCEEDING ARISING OUT OF OR RELATED TO THIS AGREEMENT OR THE PURCHASE OR USE OF PRODUCTS FROM OR THROUGH THE WEBSITE, WHETHER IN ARBITRATION OR OTHERWISE, SHALL BE CONDUCTED ONLY ON AN INDIVIDUAL BASIS AND NOT IN A CLASS, CONSOLIDATED OR REPRESENTATIVE ACTION, AND YOU AND AT3 EXPRESSLY AGREE THAT CLASS ACTION AND REPRESENTATIVE ACTION PROCEDURES SHALL NOT BE ASSERTED IN NOR APPLY TO ANY ARBITRATION PURSUANT TO THESE TERMS.

Any claims must be brought within one year of each applicable invoice or will otherwise be barred.

m. Force Majeure

AT3 will not be responsible for any delay or failure in performance of the Website or its associated products arising out of any cause beyond AT3’s control, such as acts of God, war, riots, fire, terrorist attacks, pandemics, power outages, severe weather, or other accidents.

n. Survivability

The representations, warranties, duties, and covenants made by you under this Agreement will survive the termination of this Agreement, your Account, or the Website, including, but not limited to, your duty to indemnify and defend AT3.

o. Interpretation

This Agreement will be deemed to have been drafted by both parties, and the terms and conditions of this Agreement will not be interpreted against its drafter.

p. Assignment

You are expressly prohibited from assigning your rights and duties under this Agreement. AT3 reserves the right to assign its rights and duties under this Agreement, including in a sale of AT3 or its Website.

q. Waiver and Integration

No term or condition of this Agreement or breach of this Agreement will be deemed to have been waived or consented to unless said waiver is writing and signed by the party to be charged. This Agreement is the entire agreement between the parties and supersedes all previous agreements or representations between the parties.

One Last Tip

If there’s anyone that knows the AR-15 platform, it’s the US military. As a special offer for our readers, you can get the Official US Army Manual for AR-15/M4/M16 right now – for free. Click here to snag a copy.

Can changing the trigger components change the gas level and casing ejection?

Hello!

Changing out trigger components will have no baring on gas levels or ejection patterns. This is typically relegated to upper components such at the BCG and Gas system. The buffer system in the lower is the olnly thing that can use a tune up where that stuff is concerned.

Hope this helps!

– AT3 Team

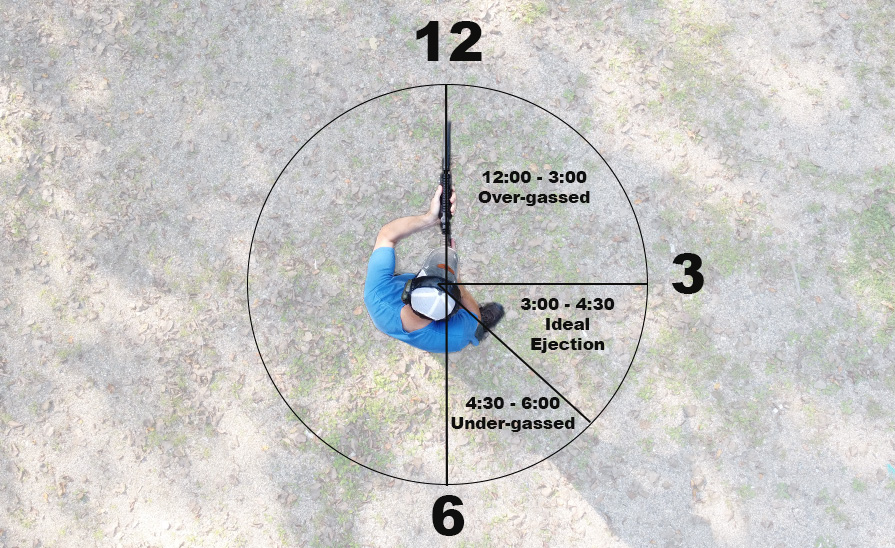

i have a 6.5″ 300 blk out i can shoot 147gr and it runs flawlessly i put 200gr thru it and it wont pick up the next round its ejecting at the proper 3 to 4:30 the buffer that it has is 2.975 oz shoot 1 rd have to rack another rnd in to it proper ejection very confused please help

thank you

jeff bryan

Hello Jeff!

Had a powow with the rest of the team and given this unique situation we came up with the following:

1. First check what your magazine is. If we are working with an ordinary M2 or M3 PMAG they tend to have feeding issues with heavier grain weights of 300BLK. This is why Magpul makes 300BLK specific magazines that work with all grain weights. So check the mag and try a different one for an affordable testable first step.

2. If the magazine is not the issue we should turn our attention to the buffer system. We understand that the ejection pattern is ideal. With slight adjustments it should be able to remain in the ideal range and still function. We would suggest to moving to an adjustable buffer in order to dial things in or one step heavier in order to better troubleshoot.

3. Lastly if those two options do not pan out it may be a barrel/gas system issue. Pehaps a technical issue with the gas block or gas port. This however is pretty unlikely if everything works fine with one grain weight of ammo.

Closing thoughts:

– If it is short stroking then the ejection pattern could still hypothetically fall in a near ideal range but this would not make a lot of sense given the already light buffer (unless you have a hefty spring we do not know about). This would be a gas system issue.

– If the bolt is moving so fast that it returns before the magazine has time to toss up another round then the ejection pattern would likely demonstrate overgassed symptoms. This would be where the brass would be going in front of you. This would be a change to a heavier buffer and a mag change if it wasn’t the right kind. Or an adjustable gas block at the very least.

Without having the gun right in front of us and seeing the issues in person it will always be tough to diagnose. Our suggestion would be to follow the breadcrumbs in those first three points. Please let us know if you have any other questions and feel free to reach out to our customer service as well.

Hopefully this was of some help.

Safe shooting!

– AT3 Team

Proper BCG speed is the key. I had a pistol length 300 BO that ejected to 5:00 no matter what I tried. I installed an adjustable block and left it open. Talking to the manufacturer we decided it was over gassed to the point the bolt was moving forward before the empty completely cleared and the bolt was bouncing the case off the front of the ejection port. Tuning the gas down solved the problem.